A Medical Device Producer Optimizes Supply Chain and Diversifies Supplier Base to Reduce Cost and Minimize Disruption

Situation

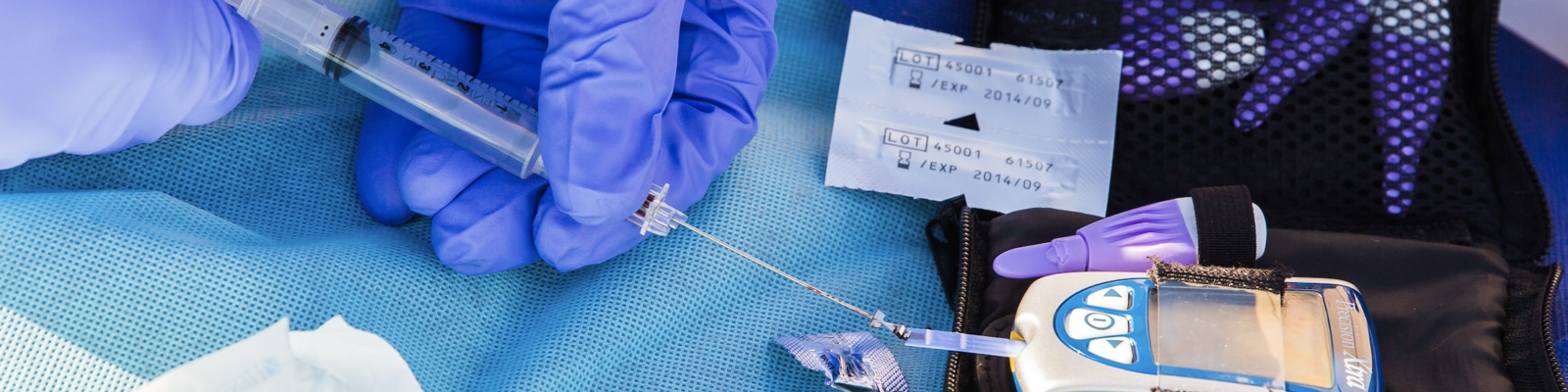

A leading producer of daily-use insulin pen needles, syringes and select complementary products for human and animal diabetes care markets, was looking for consulting support to improve supply chain efficiency and identify secondary or alternative source to de-risk and further diversify existing supply base.

Compounding the challenge across all was the limited internal capacity and capabilities of product development, procurement, technical and engineering, and warehouse distribution for efficient operations. In addition, the heavy reliance on a major supplier and lack of secondary or alternative sources puts the company at significant risk of production and distribution disruption in case of macroeconomic or geopolitical issues.

ARGO-EFESO’s Actions

- ARGO-EFESO evaluated all aspects of the operation as well as ongoing improvement efforts and their results and provided a list of potential operational improvements and associated risks with impact on EBITDA and cash flow

- Overall project divided into 5 work-streams across all functions

- Identified production improvement areas and developed action plans to reduce direct labor by 30%

- Conducted freight data analysis and recommended negotiation strategy to renew inbound and outbound freight contracts with overall freight reduction of 8%

- Setup new inventory safety stock level based on sales forecast and supply chain lead time, reduce finished goods inventory by 22%

- Recommended alternative suppliers’ qualification from low cost countries and the action plan, estimated material and freight cost savings are +$2.7M

- Implement formal Sales, Inventory and Operations Planning (SIOP) process and Standardize receiving and shipping processes

RESULTS AT A GLANCE

250

+250 SKUs to sourced from 4 different countries and predominately marketed in North America

+$2.7M

Targeted material and freight cost savings with alternative suppliers from low cost countries

30%

Productivity improvement in production shop floor

22%

Finished goods inventory reduction

Markets & Products

Medical Devices

Human and Vet Markets