Commercial Vehicle Manufacturer Uses Command Center Approach to Drive Rapid Recovery

A major manufacturer of commercial vehicles applied a tactical, mission critical approach to recover from a significant international supply chain breakdown and repair over 9,000 vehicles in 6 months to recover profitability and customer satisfaction.

The Situation

During a new vehicle model launch at assembly plants in North America in 1Q 2018, as many as 20 suppliers started missing critical deliveries, these supply chain breakdowns, in turn, caused production start-up issues. By March 2018, shortages of essential parts began to significantly affect POA (Point of Application) performance and red-tagging in the assembly lines. At two of the assembly plants, the accumulation of problems started to impact “on-time delivery,” and daily first pass yield sank as low as 30%. Plant organizations at several Mexico-based suppliers and at some in the US were unprepared for this type of crisis; our client thus had to deploy “boots-on-the-ground” resources to assist local teams in the crisis management and recovery effort. Efforts were hampered by traditional procurement practices, with their primary focus on cost reductions and piece price, rather than total landed cost. These metrics encouraged purchasing to continue making decisions that regularly impacted quality and delivery from critical suppliers.

The logistics and inventory management issues also began to cause a shortage of all types of components during efforts to improve conveyance and material handling in several of the vehicle assembly lines. As a result, “Point of Use” best practices, labor productivity, and parts availability suffered. The client had no choice but to move incompletely assembled vehicles to storage areas on- and off-site as they came off the production lines, balancing resources and parts for production and repair as parts were received. The sites quickly ran out of room to store vehicles, and delivery delays impacted customer satisfaction and sales.

The final effect of these problems was that 3,500 vehicles were sent off-line during Q2 2018.

ARGO-EFESO’s Solution

ARGO-EFESO developed a Crisis Response Command Center to restore critical supplier production/deliveries and repair operations to pre-crisis levels.

We began by establishing a central command center at the company’s US headquarters, and satellite command centers at their Mexico and US assembly plants. ARGO-EFESO next assigned “boots-on-the-ground” resources to seven of the client’s key suppliers and implemented a system to prioritize delivery of critical parts considered by impact on POA performance. With ARGO-EFESO taking the lead, the set-up of the recovery command center included:

- Created “Dynamic Work Design” visual management boards to monitor, track, and cue intervention on operational issues at suppliers and assembly plants

- Created and facilitated virtual cross-functional teams using visual boards to identify problems, determine actions, assign accountability, and track resolution in near real-time — purchasing and logistics provided vital members of this virtual team

- Led virtual problem-solving sessions to fix quality at the source in manufacturing, suppliers, and logistics, by deriving root causes and implementing countermeasures

- Oversaw supplier production control & scheduling at supplier premises to better align resources to demand

- Intervened downstream in transportation operations to prevent disruption to components and finished vehicle logistics after delivery from the plants

- Established a production cadence that aligned everyone in producing the right components at the right time in the right quantities

- Stood-up a dedicated rapid response repair line to establish flow and standard work after the final assembly line

Implementing the Solution

ARGO-EFESO collaborated with the client to assess their existing internal resources; the assessment revealed that they did not possess either the bandwidth or expertise to manage simultaneous breakdowns at suppliers’ plants, while also optimizing production and repairs at the assembly sites. ARGO-EFESO’s role was to lead, facilitate, and coordinate production & repair activities, from suppliers through repair and vehicle testing in the facilities. Rapid recovery in the Mexico assembly plant led to our establishing the same format in the US facility.

The shared goal was to create an environment in which the team would consistently and promptly identify and solve problems, thereby minimizing or preventing impact on production, while aggressively repairing off-line vehicles. Through a disciplined Lean Continuous Improvement approach, we were able to accelerate and achieve positive results recognized throughout the company leadership team.

Results Summary

- Repaired over 9,000 vehicles in six months.

- Increased Point of Use (POA) performance

- Established standard work at suppliers, repair operations, and logistics, streamlining end-to-end operations through to their customers

- Redesigned work cells and job methods to enhance flow and increase production capacity

- Identified and eliminated bottlenecks in shipping to increase overall shipping capacity

- Increased total production output at key suppliers by 55%

- As a result, the company was able to deliver backlog vehicles to customers and minimize impact to customer satisfaction. The forward-thinking actions taken by the company leadership team to engage ARGO-EFESO significantly contributed to stronger than anticipated performance. The collective team-effort to implement and sustain a Crisis Response Command Center solution helped the company recognize the need to shore up weaknesses in their supply chain, enabling them to respond more quickly in the future.

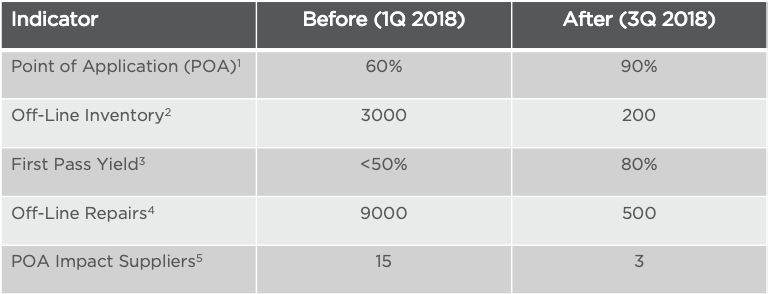

1 Average Point of Application for the two major assembly plants affected (Mexico and Ohio)

2 Total off-line inventory at two major assembly plants – beginning of supply chain issues April 2018

3 First pass yield rate at main US vehicle assembly line

4 Off-line repairs corresponds to total number of rejected vehicles over the period of time

5 Number of suppliers missing deliveries and impacting POA with “boots on the ground” teams

Conclusion

In times of crisis, team members need a clear path for rapid, aligned response to emergent situations and fluctuations in critical resources. This path is even more vital in highly-complex environments like vehicle assembly lines, which involve many thousands of parts and rely on a global network of suppliers.

This case clearly shows that when functions like purchasing and supplier development become disjointed from production and supply chain, they will inadvertently pursue conflicting priorities, and overall system performance will suffer. Crisis Response Command Centers align the team around a common purpose.

ARGO-EFESO’s involvement was surgical, swift, and rapidly generated significant results. Participation was required from every link of the value chain, from HQ and assembly plants, through suppliers’ shop floor operations, to distribution centers’ transportation coordination functions. Digital tools and video teleconferencing for real-time, virtual problem-solving are a critically important enabler for this kind of remote participation. Such tools should be regarded as an indispensable resource when establishing Rapid Crisis Response Command Centers.

Testimonial

“The team was very impressed with the people, process discipline and innovative thinking that ARGO-EFESO brought to address a serious supply chain crisis. Their use of Command Centers in our headquarters and two of our facilities had an immense impact on our ability to minimize the impact to profitability and customer satisfaction. Without their knowledge and capabilities to execute the end-to-end delivery of materials and vehicles, we would not have been able to maintain production and repair simultaneously. ARGO-EFESO provided coaching and leadership to our teams on methodologies and best practices that made us confident in our ability to respond better and faster should a similar situation arise in the future”

-VP Manufacturing of a commercial vehicle manufacturer

About the Authors:

Jorge Mastellari is Senior VP and Partner at ARGO-EFESO. His background spans across multiple industries ranging from Industrials to Private Equity and Oil & Gas. Prior to joining ARGO-EFESO, he was a Project Manager with McKinsey & Co. [email protected]

Alan Free is Senior VP at ARGO-EFESO and currently leads the Chemical, Energy, and Natural Resources industry practice. Prior to joining ARGO-EFESO, he worked for a variety of clients as a trusted advisor. a[email protected]

Mark Searcy is a Director at ARGO-EFESO with extensive experience in Operations, Supply Chain and Continuous Improvement across a variety of industries including defense, telecommunications and contract manufacturing. m.searcy@argoconsulting.com