Safety, Health, Environmental and Sustainability (SHES)

The Situation

ARGO-EFESO was asked by a global leader in Catalyst Manufacturing for the Chemical and Oil and Gas industries to perform an analysis of their Safety, Health, Environmental and Sustainability (SHES) organization and processes against the Vision Zero Framework and ARGO-EFESO’s Best Run Chemical Operations Playbook that includes best practices for Safety, Health, Environmental and Sustainability (SHES) to identify gaps and prioritize areas of focus.

Through observation, interviews and data analysis we found an overall ineffective and inconsistent SHES program across multiple sites. Most notable included a lack of a SHES Strategy and Management System; immature work processes and disconnected with sustainability.

More specifically was insufficient focus or stability in areas such as organizational alignment of SHES, roles and responsibilities, process safety management, systems and standards, management of change, cascading and leading KPI’s, and problem-solving of root cause and actionable countermeasures.

Achieving sustained positive results in SHES requires unrelenting focus and dedication, as a single mistake or equipment failure can lead to catastrophic results. People make mistakes and equipment can fail. Having robust processes in place to prevent these occurrences is crucial to proactively safeguarded against these events.

ARGO-EFESO’s Actions

ARGO-EFESO was asked to solidify the SHES foundation with the overall objective to define and build a comprehensive, global, world-class SHES framework with the right strategy, governance, culture and work processes.

To do so, ARGO-EFESO identified two workstreams to begin the journey:

1. Framework: First and foremost was to fully define the SHES framework including strategy, roles and responsibilities, reporting structure and governance to establish a new culture, and work processes putting SHES in the forefront. Extensive, collaborative, objective discussions took place to develop the right functional strategy and processes that aligned with the corporate strategy as well as Vision Zero Framework. A RACI Matrix was developed to add clarity to roles and responsibilities to enable alignment and ownership. The final piece that was put in place was a communication plan to ensure two-way communication and feedback in order to sustain collaboration and improvement.

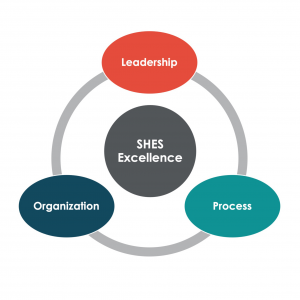

SHES Excellence

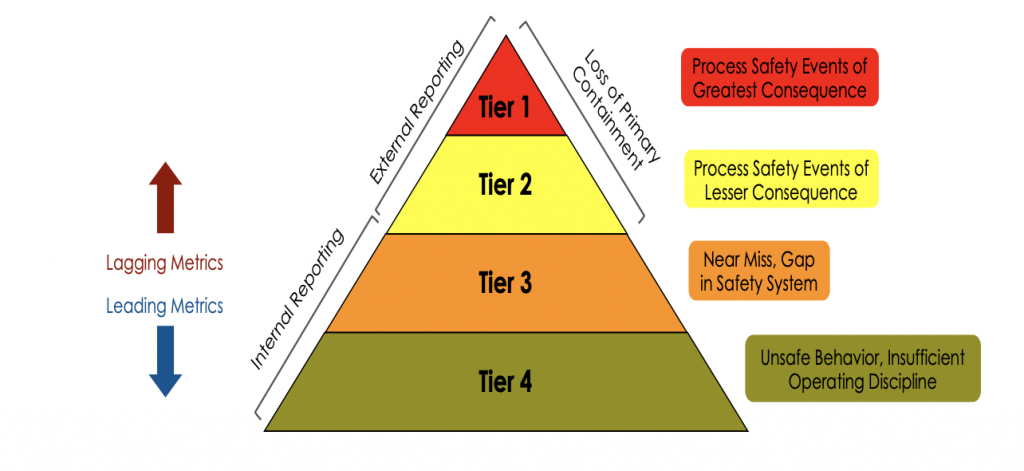

2. Key Performance Indicators: – Step two was to drive the emphasis on cascading KPI’s to all levels of the organization to proactively prevent incidents. ARGO-EFESO applied its collection of simple and practical leading and lagging indicators to be embedded and easily visible in operational dashboards. The real impact of KPI’s lies not in the numbers, but in the actions taken to correct performance. Therefore, ARGO-EFESO applied a closed-loop performance management system to identify proper actions and countermeasures. Lastly, an implementation plan was designed to identify the steps necessary to achieve successful deployment to all sites globally.

SHES Process Safety KPIs

Results

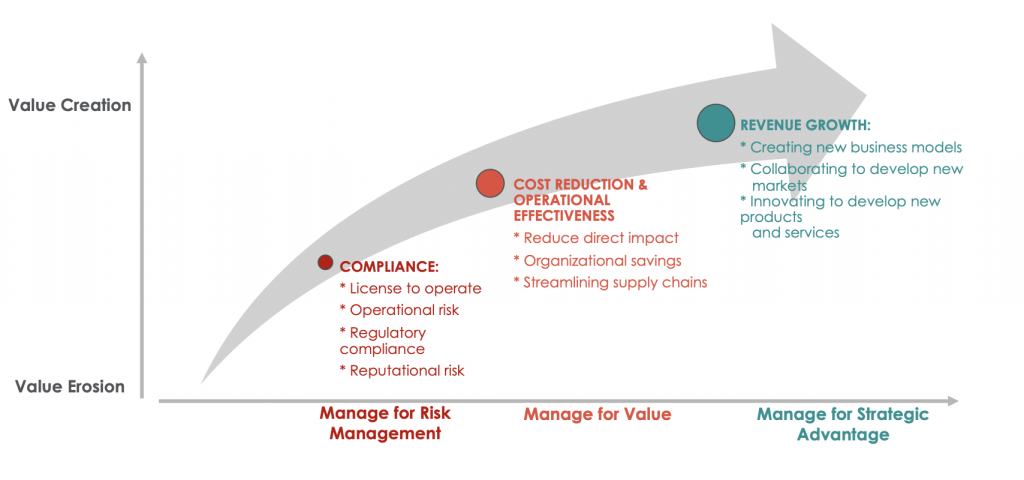

The result was a comprehensive, global, world-class SHES framework, with input to leverage sustainability, with the right strategy, governance, culture and work processes to enable SHES to become a strategic advantage for the company. A communication plan and an implementation plan were provided to enable a successful global execution and start the client off on a successful and safe journey of value creation and revenue growth.

SHES Value Creation