At a Glance

At a Glance

The Problem:

In today’s margin-pressured environment, most companies recognize the need to improve productivity and reduce costs. However, many respond solely with reactive, fragmented, and unsustainable cost-cutting initiatives that can impair growth. Rather than settling for superficial savings, companies must structurally reshape their cost base to unlock long-term enterprise value. This means pursuing cost optimization in tandem with value creation.

The Solution:

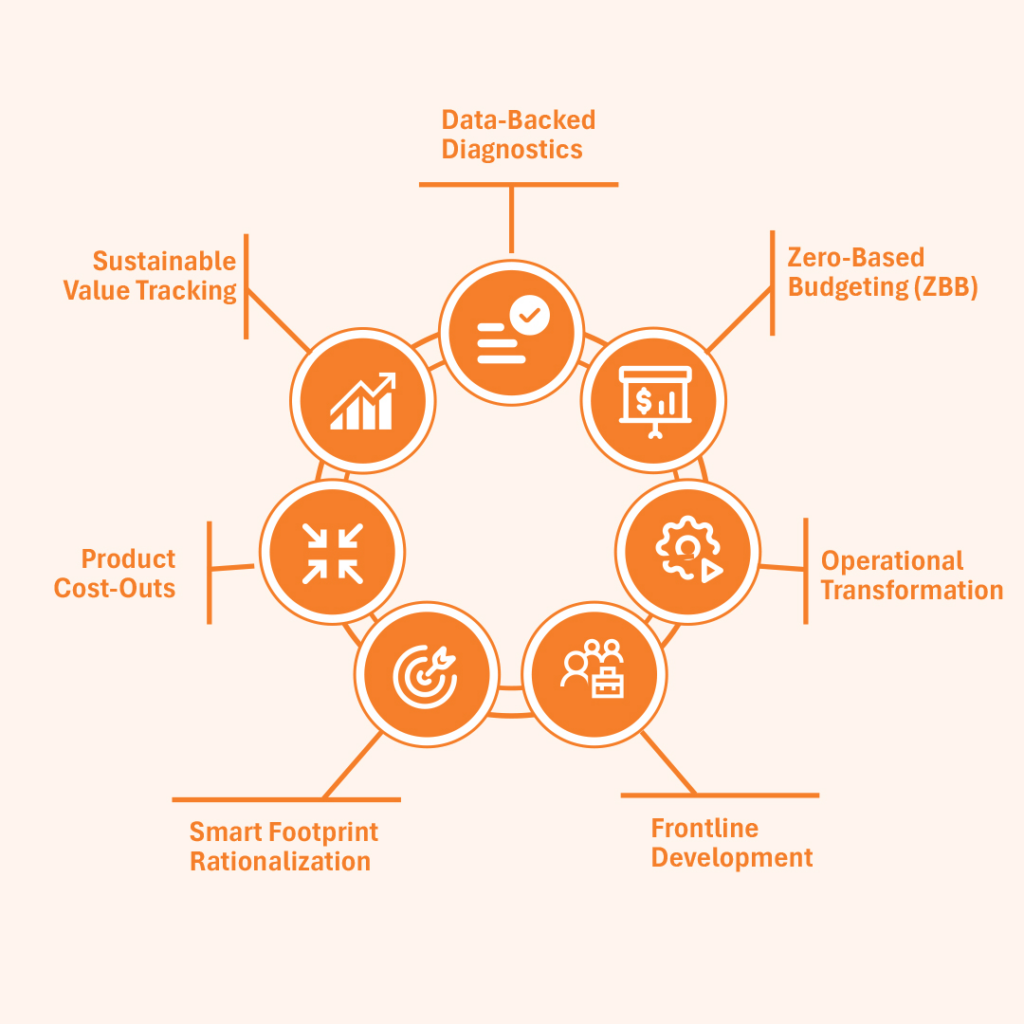

To achieve this, companies are leveraging a set of corporate capabilities that rigorously address both short-term cost-savings opportunities and long-term strategic growth. These include:

- Data-Backed Diagnostics

- Zero-Based Budgeting

- Operational Transformation Goals and Detailed Plans with Available Resources

- Frontline Development

- Smart Footprint Rationalization

- Product Cost-Outs

- Sustainable Value Tracking

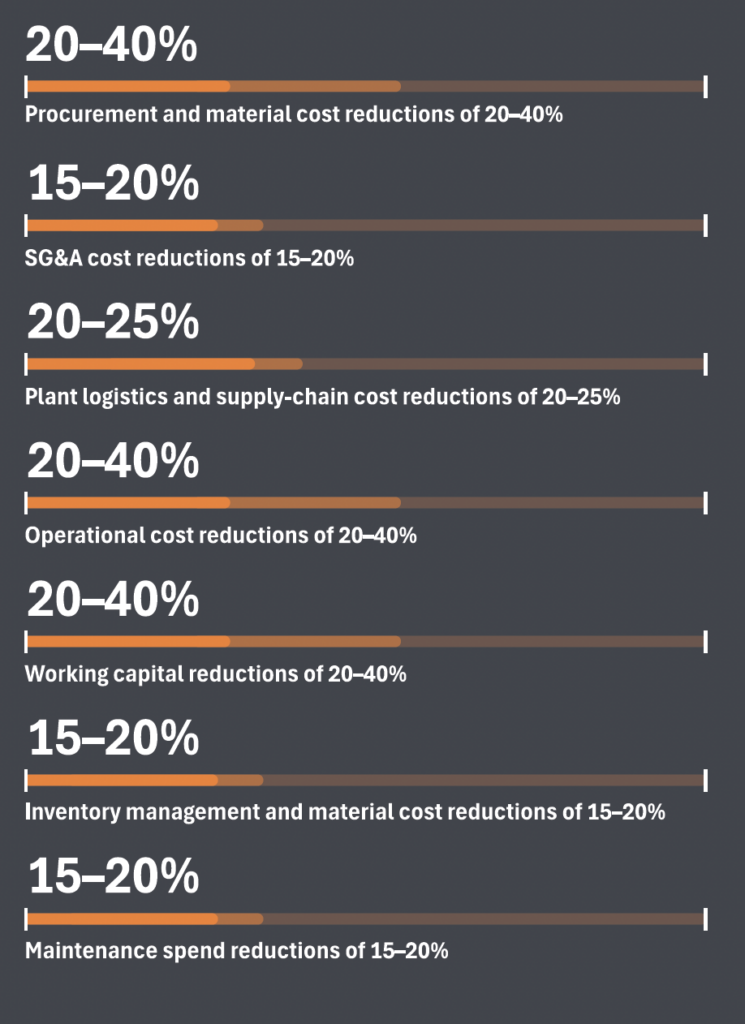

By applying these capabilities, organizations can systematically target common cost areas, pull specific levers, and deploy tailored improvement methods. The most immediate and substantial savings are typically realized in SG&A, procurement, operations and maintenance, supply chain, and quality.

Other areas, while requiring more time to execute, yield meaningful savings over the long term—such as product development, capex optimization, and SKU rationalization. Additionally, current events and the organization’s structure may create opportunities for significant cost reduction in information technology, sales and marketing.

When taken together, these areas represent a powerful opportunity for overall cost reduction. Across industries, companies have achieved total savings of at least 20–25% of operating expenditures

Examples of Impact:

- A global chemicals company redesigned its operating model across 10 sites, reducing SG&A by 18% and achieving $50M in recurring EBITDA gains.

- An automation equipment manufacturer implemented ZBB and AI-supported sourcing, realizing $3.4M in OpEx savings within nine months.

- A refinery applied lean workflows and reduced contractor headcount by over 60%, saving $100M while boosting asset uptime.

- An industrial components business rationalized its product SKUs and plant network, cutting $15M in logistics and material costs.

- A consumer goods firm embedded cost KPIs in daily management and linked incentives, sustaining a 22% SG&A reduction over two years.

Smarter Cost Takeout Today, Strategic Positioning for Tomorrow

Even in mature businesses with previous cost initiatives, structured and strategic approaches continue to uncover savings while enabling reinvestment. Smart cost takeout is both an operational lever and a long-term value driver.

In today’s margin-pressured environment, most companies recognize the need to improve productivity and reduce costs. However, there is a heightened sense of urgency given the impact of tariffs and overall economic uncertainty. Rising material, labor, and logistics costs are impacting earnings and squeezing profits. A knee-jerk response is to “cut costs,” but such initiatives are usually reactive, fragmented, and ultimately unsustainable and damage potential for growth.

What’s needed to address today’s challenging business conditions is cost optimization that goes hand in hand with value creation and positioning for growth. A smarter cost takeout approach is strategic, meaning it is aligned with long-term business goals and growth plans. It is also data-driven, as it is built on proprietary benchmarks, activity-based cost models, and operational diagnostics. Furthermore, it is sustainable, because it is embedded into ways of working rather than being limited to adjustments in budget lines. The true opportunity lies not in superficial savings, but in structurally reshaping the cost base in order to unlock long-term enterprise value.

Value-Driven Cost Reduction

Opportunities to reduce costs in a company range from quick hits that deliver much-needed near-term relief to strategic decisions that drive long-term savings and value. These savings are found in the cost of goods sold, such as direct material, labor, and overhead, as well as in operating expenses that impact operating profitability and EBITDA, including sales and marketing, administrative, and R&D costs.

Corporate capabilities being wielded to rigorously address all potential opportunities today while preparing for a value-driven future include:

Corporate capabilities being wielded to rigorously address all potential opportunities today while preparing for a value-driven future include:

- Data-Backed Diagnostics: Analysis of financial, operational, and market data uncover inefficiencies at a granular level, for example from procurement patterns to labor productivity. Cost drivers are mapped across functions and linked to performance benchmarks, enabling fast identification of where inefficiencies exist. This is often supported by AI capabilities, allowing interventions that quickly deliver the greatest impact.

- Zero-Based Budgeting (ZBB): Companies often base their budgets on prior years, which in turn shapes their current budgets, expenses, and overall costs. In contrast, ZBB erases that approach and instead encourages leaders to build their budgets from the ground up, aligning spend with purpose and eliminating legacy inertia. Budgets are reconstructed and justified line by line, item by item. This creates discipline in managers and leaders to question everything and the assumptions therein.

- Operational Transformation: Lean tools, best practices, automation, and process redesign structurally reduce effort, unlock efficiency, reduce costs, and create sustainable operational discipline. The goal is not just fewer people or lower spend; instead, it is faster cycle times, better output, and scalable systems. Application of standard work, meaning the current best, safest, most efficient way to work, then sustains improvements and cost savings going forward. Simplifying, codifying, and, where possible, digitizing standards can significantly boost productivity, improve cost predictability, and accelerate onboarding amid today’s critical skills shortage.

- Frontline Development: The retirement of seasoned operators is leaving behind skills gaps, as less experienced employees often lack the knowledge to spot improvement and cost-saving opportunities. Therefore, building a competitive workforce and supportive systems like daily and visual management enables a right-sized, engaged frontline to make real-time decisions throughout the day that improve operations and control costs while operations are underway.

- Smart Footprint Rationalization: The size and shape of a company, including facility roles, cost-to-serve, labor economics, and asset ROI, is examined with footprint rationalization. As a result, proactive measures such as idling underutilized assets, divesting non-core operations, or shuttering inefficient plants are essential to correcting market imbalances, restoring pricing discipline, and designing an optimized network that aligns with strategic goals.

- Product Cost-Outs: The design of the product, service, system, supply network, and so forth dictates the cost structure going forward to make and deliver goods. This can involve the selection of less expensive and more readily available supplier materials and components; reducing the number of components within a product; creating products that are easier to produce and that minimize waste and rework; and improved utilization of existing processes, equipment, and resources (reduced overhead).

- Sustainable Value Tracking: Every initiative undertaken should be measured by its tangible EBITDA impact, with operational KPIs clearly translated into financial terms. This requires robust financial models, performance dashboards, and incentive alignment that reinforce cost discipline and continuous improvement across functions. These also provide the capability to govern, track, and sustain value capture well into the future.

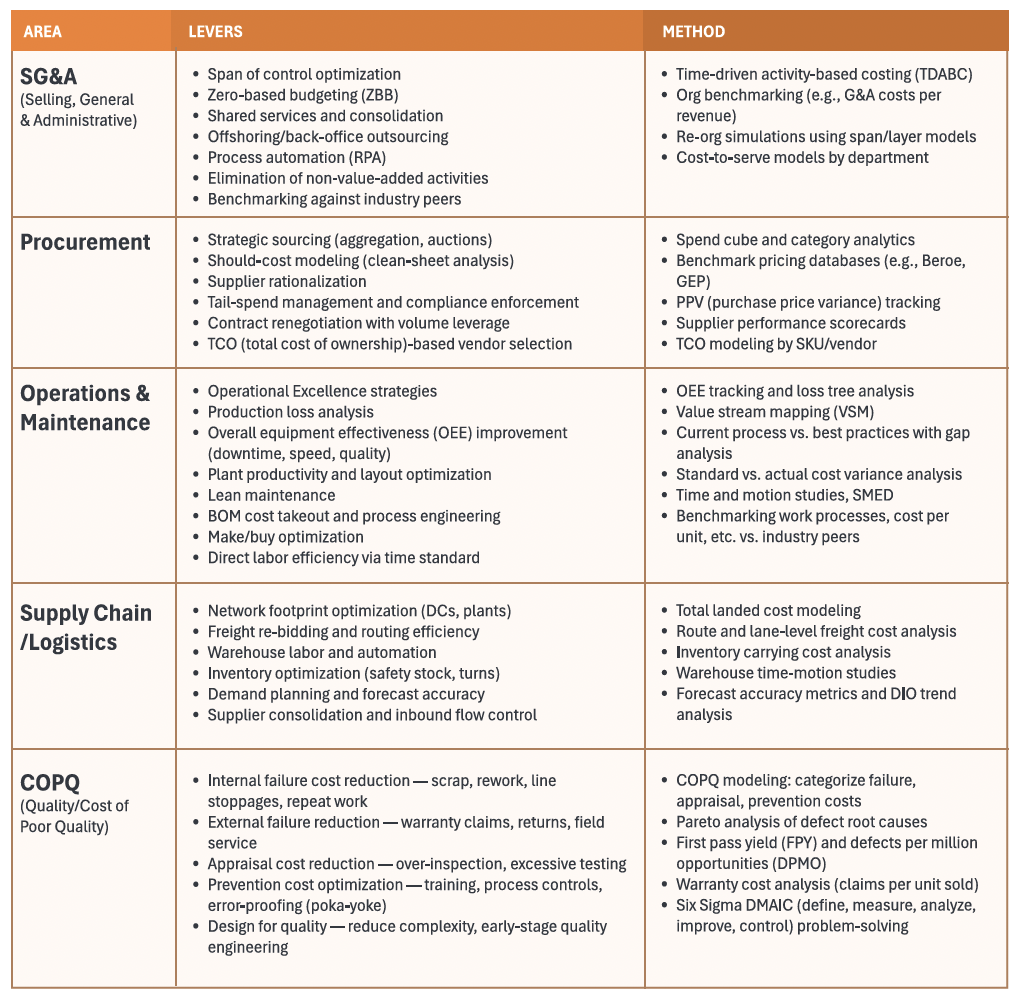

Cost-Saving Targets, Levers, and Methods

All companies share common cost structures and can pull levers for cost reduction specific to each area, such as the use of shared services and consolidation to address SG&A costs. Levers are supported by a wide range of improvement methods tailored to each cost category, like total-landed-cost models to facilitate footprint optimization of the supply chain.

Most companies find the largest and fastest savings in areas of SG&A, procurement, operations and maintenance, supply chain, and quality (see Exhibit 1). Other areas take longer to execute but also can deliver sizable savings, such as product development, capex optimization, and SKU rationalization. Additionally, some areas offer substantial cuts based on current events and organizational structure, including information technology, sales and marketing. Taken together, these areas present significant overall savings.

The primary objective in targeting these areas is cost savings. However, this does not necessarily mean headcount reduction. In fact, true cost optimization may involve preserving, or even expanding, staff to unlock and sustain value. For instance, enhancing procurement processes rarely leads to large layoffs, and boosting throughput typically requires maintaining current personnel to support higher sales volumes. Similarly, selectively adding production lines or opening new facilities as part of a network‐footprint strategy can actually increase the workforce rather than shrink it.

- In dynamic business environments, workforce strategy must balance financial goals with company culture. The following five scenarios illustrate typical headcount implications:

- M&A-driven organizations: Redundant support functions are identified and trimmed. Workforce reductions are expected in order to eliminate overlap.

- Performance-driven restructurings: When targets aren’t met, staffing levels are aligned with current financial realities to maintain core operations.

- Basic turnarounds: Surgical, organization-wide cuts focus on underperforming roles to shore up cash flow and stabilize the business.

- Good-to-great transformations: Best-practices deployment, automation, and digitization investments enable and accelerate productivity gains, which may lower headcount.

- Rapid growth and new-market entry: Greenfield expansions or new business units demand aggressive hiring.

Cost Takeout Conclusions

Companies that routinely analyze and optimize cost structures and establish new operational strategies and programs to drive performance improvement, position themselves for growth. They achieve quick wins such as immediate cost reductions and operational improvements. In addition, they enable longer-term benefits through transformed processes, systems, and footprints that ensure ongoing value-add and cost containment. Most importantly, they achieve cost savings of up to 20–25% of operating expenditure (OpEx) spending, which boosts the bottom line and puts them at a competitive advantage. Specific savings can include:

Cost optimization should be viewed not merely as a response to pressure but rather as a catalyst for transformation. Companies across many industries are achieving short- and long-term savings beyond what they previously thought possible. The following examples highlight how this impacts the bottom line:

New Organizational Model and Operating Standards in the Chemical Process Industry: With mounting cost pressure, underperforming assets, and disjointed organizational structures and work processes across many global sites, a chemical company had to transform operations to survive. The company developed new operating standards and an organizational model that was deployed globally to run, improve, maintain, and operate safely with highly reliable assets that predictably deliver quality products. A robust change management program was also implemented to shift the culture and drive sustainment. This transformation program accelerated productivity and cost reduction, improved quality, and gained additional capacity release, leading to a $50 million EBITDA improvement annually and a sustainable foundation to drive future growth.

Cost Capture and Process Improvements in Equipment/Automation: An equipment/automation company identified up to $3.4 million (12% of total OpEx) in potential savings across a network of six plants that could be achieved in the near term. Four opportunities could be addressed immediately by capturing direct, indirect, and SG&A savings, yielding approximately $600,000 in annual reductions. The remaining 80% required process improvements, but overall, more than 50% of savings could be achieved within six months and nearly all savings captured within nine months.

AI-Enabled Data Analytics in Automotive: A procurement-focused project at an off-highway automotive company resulted in savings of €30 million (approximately 16% savings on the total purchases of the company). Using an AI analytical toolbox, contracts with approximately 175 suppliers were reviewed and revised in just three weeks.

Lean Transformation for Oil and Gas: Multiple lean initiatives were undertaken at the largest site of a refinery company, as well as at two additional sites. The initiatives focused on waste elimination, visual management, and front-line KPIs in the maintenance areas. Workflow improvements reduced contractor headcount from 900 to fewer than 350 at one site and resulted in more than $100 million in savings (13% of Total OpEx).

Even during tough times when the most obvious cost areas have already been targeted, opportunities remain to deliver needed savings without inhibiting growth enablers. A smarter cost strategy is a transformation that allows companies to enter the next upcycle stronger, faster, and more focused than competitors. The emphasis should be on building a leaner, more resilient organization that is fully prepared for what comes next.

Appendix

The Authors

Chuck Deise, Senior Partner

Jorge Mastellari, Senior Partner

Bruce Work, Partner

CJ Renegar, Partner

David Sedge, Partner

Dantar Oosterwal, Partner

Iñigo Acha Orbea Bayon, Senior Consultant