Operational Excellence: Taking Productivity, Reliability and Asset Utilization to the Next Level at a Large Multi-Site Chemical Operation

Situation

- The company was under extreme pressure to improve operations to create additional capacity without capital, improve productivity and EBIDTA

- New leadership recognized the need for operational efficiency and reliability improvements to improve plant operating performance

- Speed and agility was to needed to accelerate change

- Sustaining the gains was a top priority, and the goal was to engage the entire organization in the improvement activities

ARGO-EFESO’s Solution & Approach

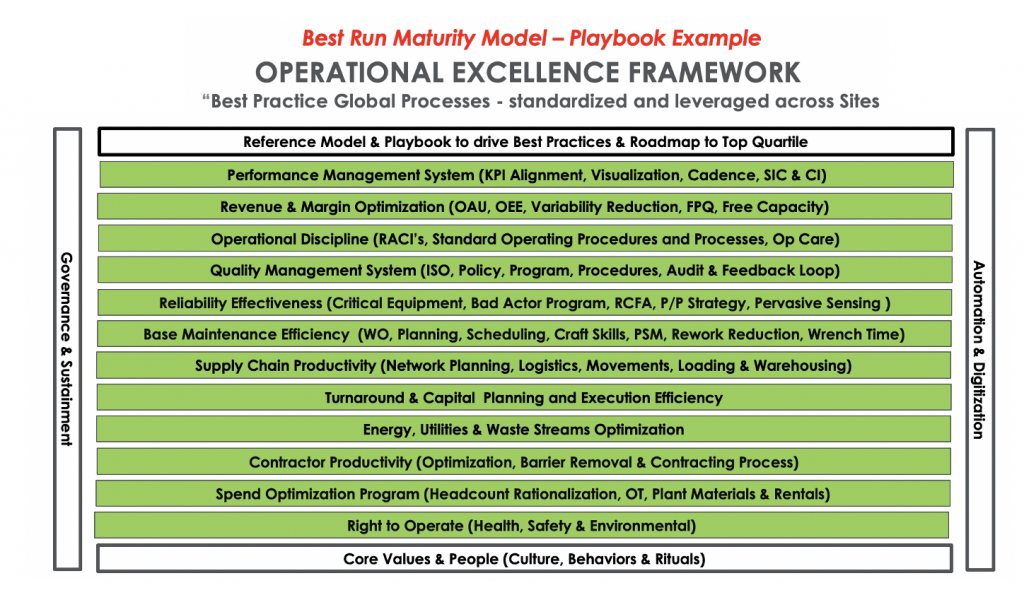

- ARGO-EFESO leveraged our Best Run Chemical Operations Playbook and benchmarked the client against best practices to create a roadmap and implementation plan to accelerate change and performance improvement

- New Operating Models and Best Practices from ARGO-EFESO’s Best Run Chemical Operations Playbook were deployed to improve processes and systems, and build a a culture of continuous improvement

- ARGO-EFESO’s Operational Excellence Framework was used as the yardstick to prioritize and implement improvement initiatives

Major Initiatives implemented:

Major Initiatives implemented:

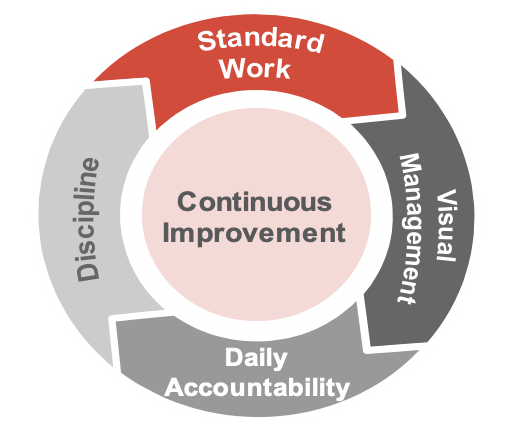

- Performance Management System to drive ownership and create an accountability dialogue to improve operations (KPI”s/Cadence/Visualization)

- Reliability Effectiveness Program to identify and mitigate bad actors, develop preventative treatments for critical equipment and shift to a proactive and predictive culture

- Maintenance Productivity Program focused on best practice planning, scheduling, good work orders to improve right first time, eliminate rework and maximize time on tools

- Overall Asset Utilization improvement program mitigate production losses

- Operational Discipline with clear roles and responsibilities and Operator Care model to eliminate defects at the source

- Training development and coaching leaders and employees to take-action and achieve lasting change

- Rigorous Continuous Improvement Program to engage the site in performance improvement

RESULTS AT A GLANCE

$46.9 MILLION

Annual pretax earnings improvements

79% to 94%

Overall Asset Utilization

17%

Productivity Improvement

42% to 77%

Preventative Maintenance Workorders

40% to 6%

Decrease in P1’s

21%

Yield Improvement