We coach your people to improve rail traffic flow and performance at lower costs

Rail logistics in downstream are regularly challenged with external forces: carriers’ pressures, supply chain disruptions and traffic congestions are just some of the variables. While Class 1 carriers are pursuing a precision rail strategy to optimize their assets and fleets, downstream operators are searching for ways to mitigate risk, achieve load / unload targets and reduce overall costs. ARGO-EFESO has deep knowledge in the sector from working with virtually every Class 1 carrier in North America.

Capabilities / Accelerators

Capabilities / Accelerators

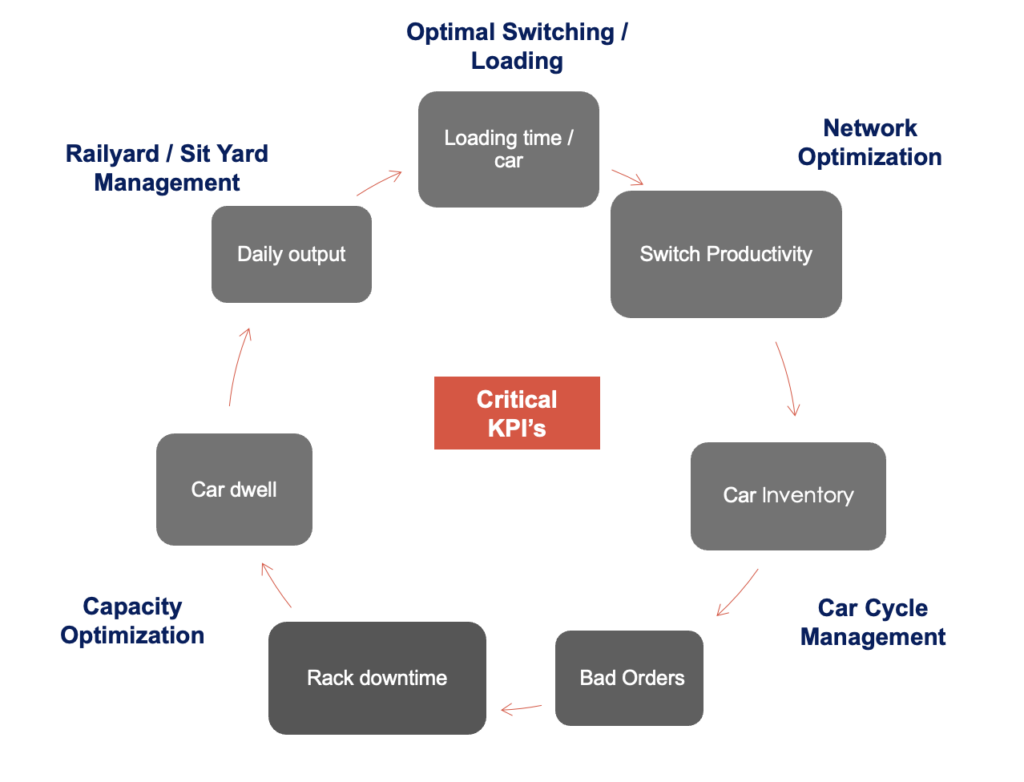

- Design and implement Rail Operations Command Center

- Re-design implement yard management system

- Re-design / re-sequence switching operations

- Re-design traffic operations workflow / optimize inside / outside fence storage

- Fleet management process and reduce car cycle dwell

- Re-design load rack operations to increase daily loads

Typical Results for Clients

- 20% to 75% Increase in Loading Capacity

- 15% to 25% Increase in Class 1 Level of Service

- 15% to 25% Reduction in Storage Costs

- 10% to 30% Reduction in Accessorial Costs

- 15% to 25% Reduction in LPO