ARGO-EFESO has 30 years of hands-on experience with 300+ projects completed where we improved maintenance practices, effectiveness, and uptime performance across industries. We have taken a practical approach pulling the key elements of TPM and RCM into our ARGO- EFESO R&M approach for the best results and “right” implementation efforts.

Total Productive Maintenance (TPM) is a strategy for improving productivity via improved maintenance practices, including maintenance plant and equipment function. At the same time, Reliability-Centered Maintenance (RCM) primarily aims to preserve system functions.

Total Productive Maintenance (TPM) is a strategy for improving productivity via improved maintenance practices, including maintenance plant and equipment function. At the same time, Reliability-Centered Maintenance (RCM) primarily aims to preserve system functions.

The best practice is to review and combine key elements of both methodologies to your maintenance program as they lead to better processes, teamwork improvement, production output and lower cost.

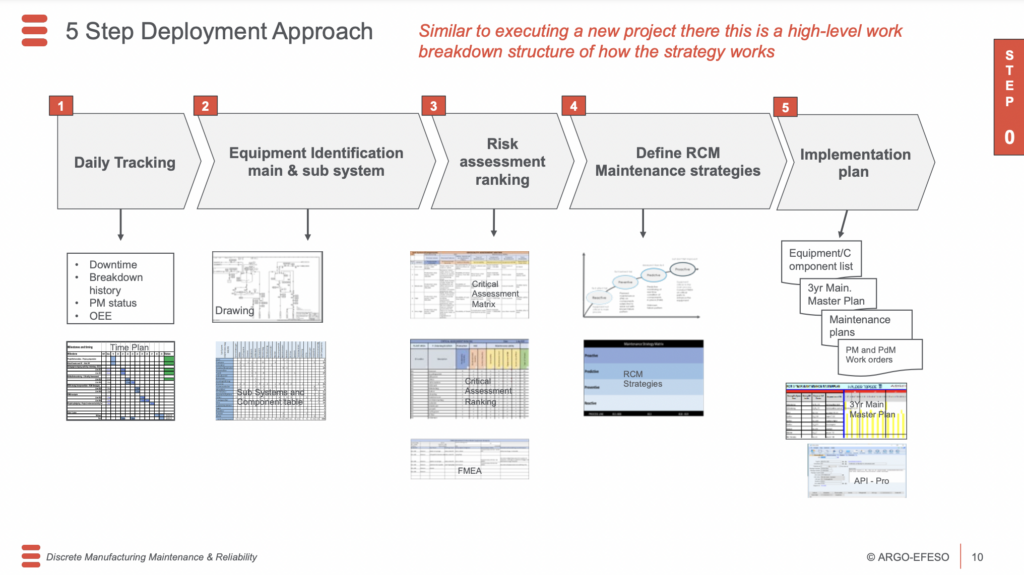

The ARGO-EFESO Discrete Manufacturing Playbook outlines the 5 critical steps of this journey:

The ARGO-EFESO Discrete Manufacturing Playbook outlines the 5 critical steps of this journey:

1) Performance Tracking Downtime and OEE

2) Equipment Identification at the Sub-system/Component Level

3) Asset Risk Assessment

4) Maintenance Strategy Selection for each Critical Asset

5) Implementation and Sustainment of overall R&M Maintenance Program

Download ARGO-EFESO’s Discrete Manufacturing Playbook to learn more about our approach and how this might be the right approach for you and your equipment.